Our team strives to continually learn and grow by exploring different technologies. For this particular project, our goal was to produce a custom retractable landing gear for the national UAV competition. The purpose of this design was to reduce air drag and enhance the vehicle’s efficiency. Retractable landing gears are typically found in airplanes that fly for long periods and at high speeds. To challenge ourselves, we decided to design a retractable landing gear for our vehicle.

Designing the Retractable Landing Gear

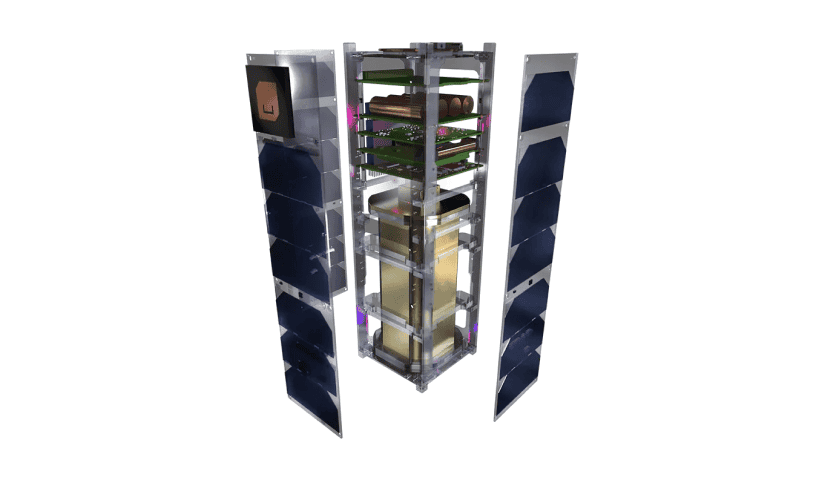

The design consists of a mechanism comprising a servo motor-linked arm, a T-slot for folding, a main column, a secondary column, an L-shaped arm to attach the wheel, a motion screw-DC motor combination to enable opening and closing, and a main housing for easy assembly. We used a medium-stiff spring to prevent impacts between the main and secondary columns and protect the mechanism.

Pneumatic systems were excluded due to potential issues with sealing and maintenance. At the top, the mechanism features a jointed assembly for full rudder motion and a motion screw that facilitates opening and closing. Additionally, the mechanism folds horizontally during retraction to optimise the use of space occupied by the wheel.

The key challenges in this project were accurately analysing the motion mechanism and manufacturing it from a lightweight yet durable alloy. While working on the necessary designs, we used Xometry’s Instant Quoting Engine to calculate costs. When we reached out to Xometry for support in manufacturing, they indicated their willingness to sponsor part production after the designs were finalised.

We required complex and durable components, necessitating CNC machining, threading, and tight tolerances. Xometry helped us produce the main column, secondary column, and the part connecting the wheel using Al7075 alloy.

Achieving Success Through Perseverance and Innovation

After a year of extensive planning, testing, flight trials, crashes, and countless retries, we competed in the TEKNOFEST 2024 Fighter UAV Competition with our fixed-wing vehicle, Dişsiz. We achieved third place in the honorable mentions and won the “Best Design” award! Despite the competition being mentally and physically demanding, it was an unforgettable and proud journey. Even after a mid-air collision with another team’s UAV, resulting in damage to our aircraft, giving up was not an option. With just 30 hours of tireless effort and no sleep, we repaired our plane at the competition site and resumed our fight in true Fighter UAV spirit.

In addition, we achieved a remarkable second place at the RoboNation SUAS’24 competition held in the United States with our rotary-wing vehicle, Şimşek, which we developed through years of experience. Representing our country and university on the international stage was an incredible honor. Despite extensive effort and sleepless nights, our vehicle suffered a collision due to organisational and technical shortcomings during the competition. Although the crash was due to the organisers’ errors, we were penalised with deduction points, which halved our score. Nevertheless, we secured second place out of 69 teams.

Preparing for Future Competitions

This year, we plan to participate in the TEKNOFEST Fighter UAV Competition and the SUAS (Student Unmanned Aerial Systems) competition in the United States. Our goal is to produce two new vehicles: one rotary-wing and one fixed-wing. In both competitions, we are striving for first place!

Learn more about ITUNOM and follow them on Linkedin.

Have you ever worked on a challenging UAV project? Share your experiences and the innovative solutions you used to overcome obstacles!

Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)