- Industry: Transportation, E-mobility

- Manufacturing Processes: FDM 3D Printing, MJF 3D Printing, Injection Molding

- Materials Used: ABS, PA12, PA6-GF

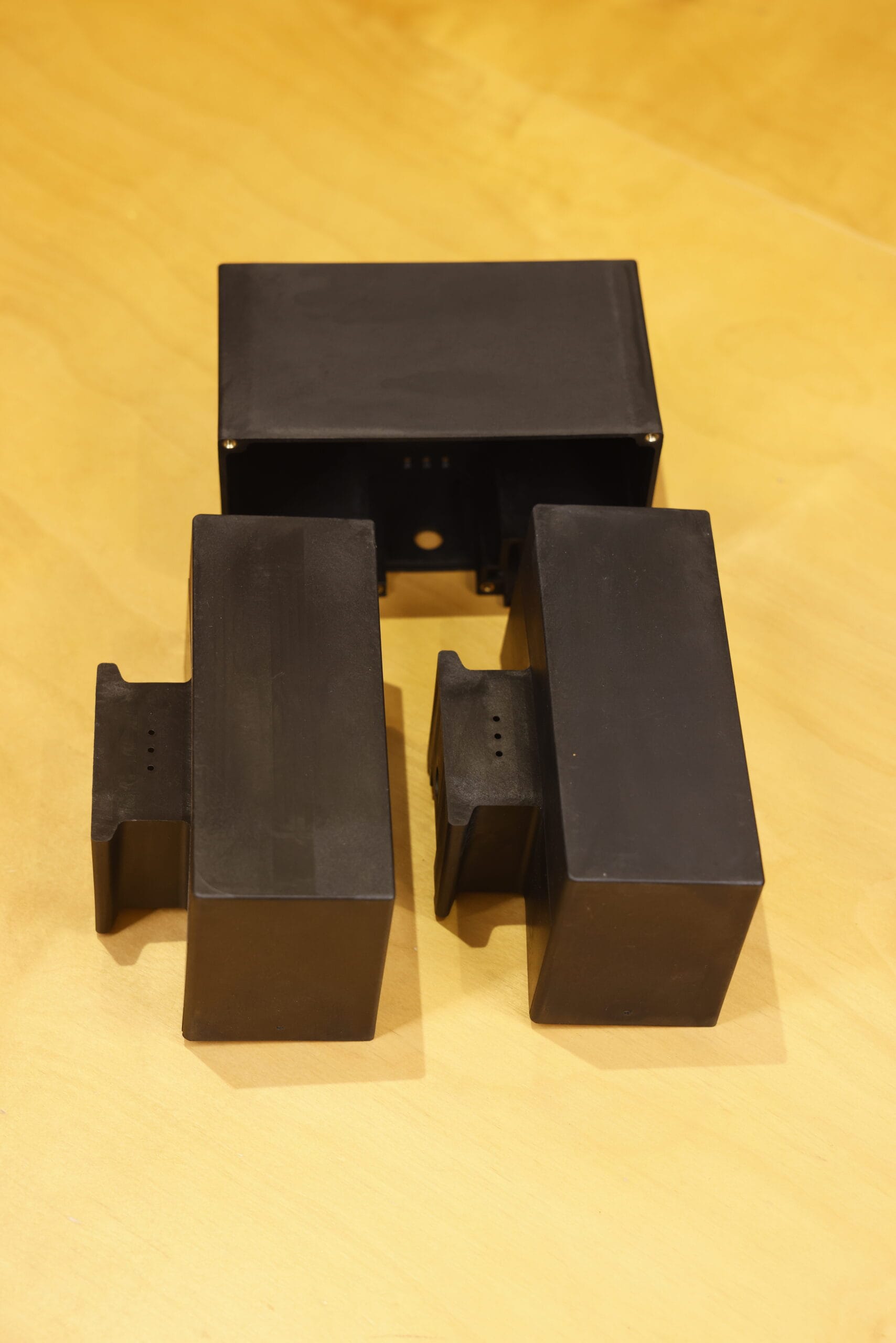

- Challenge: Produce ergonomic, durable plastic battery housings and brackets that keep the bike’s weight low; avoid the cost and time setbacks of working with multiple suppliers; quickly move from frequent product iterations to mass production.

- Solution: DfM analyses and engineering support; Target Price Orders and a global supply network to meet Byqee’s needs from R&D to mass production—all on one platform.

Byqee: A Trailblazer in E-Bike Transformation

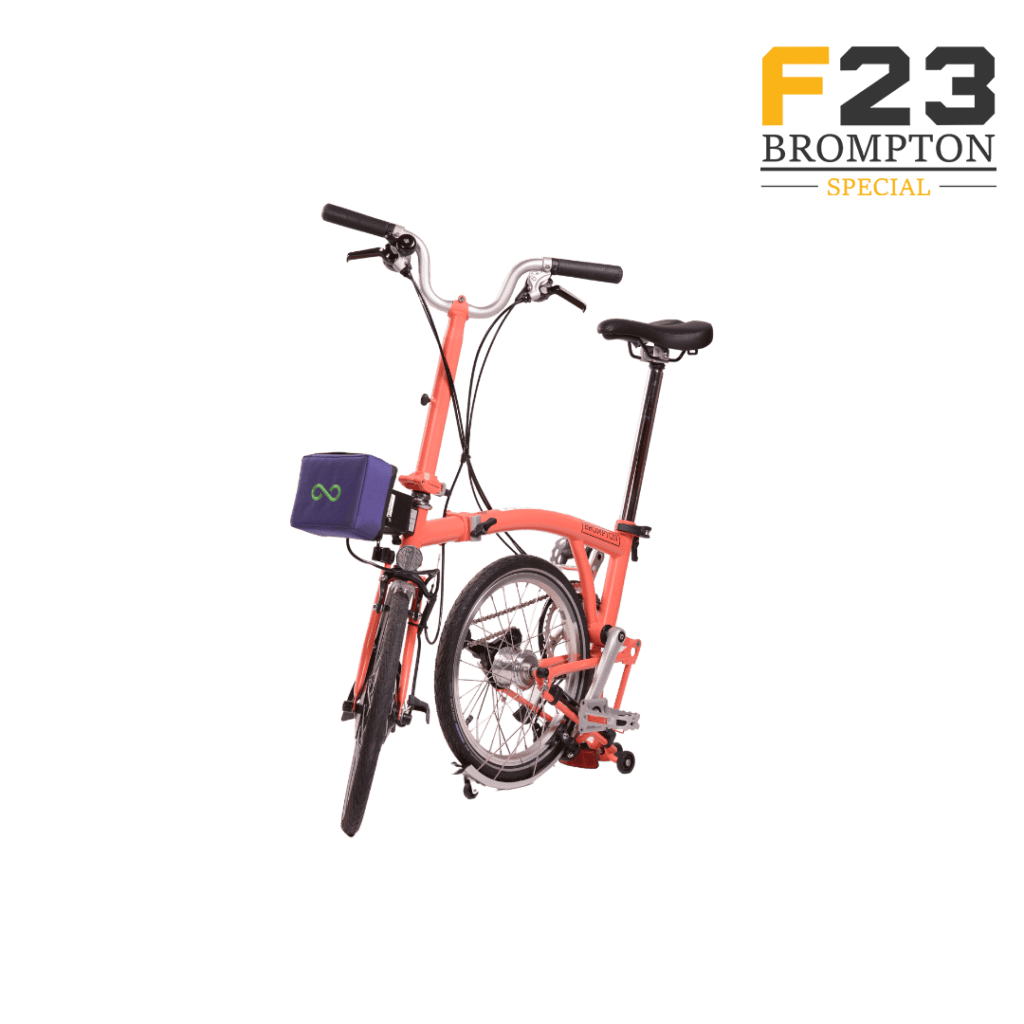

Founded in 2020, Byqee is a tech/startup brand that electrifies traditional bicycles using a lightweight conversion kit. Its co-founders, Eda Işık and Burak Işık, aim to provide sustainable and ergonomic solutions for urban mobility. Besides their electric bike conversion kit, Byqee also focuses on battery renewal and battery packs for various electric vehicles.

- Focus on Lightness: Byqee’s kit adds minimal weight to your bicycle, preserving user comfort and ergonomics.

- Battery Technologies: From renewing existing batteries to achieving an impressive range of up to 200 km.

- International Vision: Receiving investment from İTÜ Çekirdek and winning the “Most Beloved Mobility Brand” award at the 2023 Autonomy Mobilité Fair in Paris, Byqee continues to grow globally, offering fast delivery in both Türkiye and the EU region.

Challenges: Lightness, Design Revisions, and Affordability

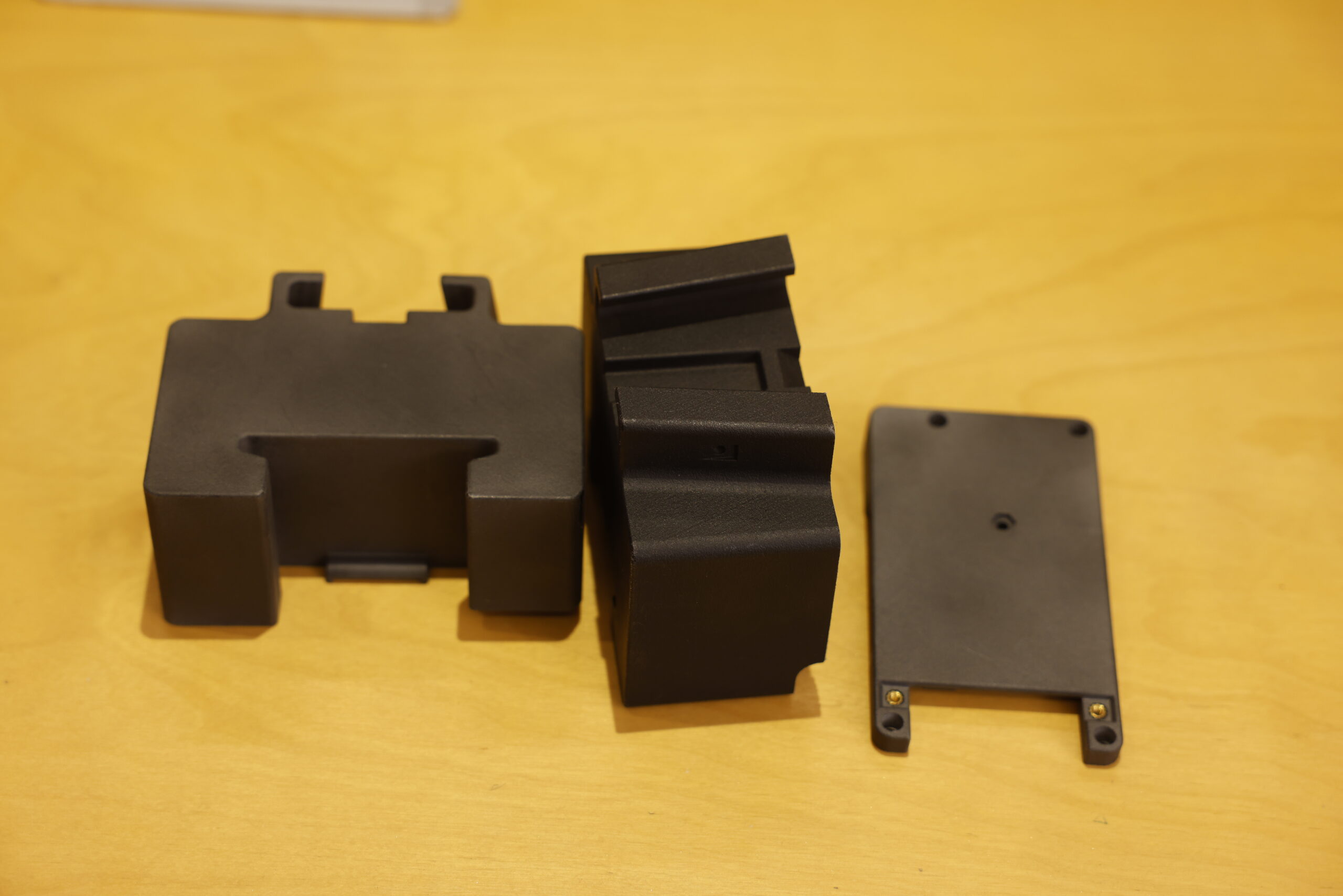

Initially, Byqee’s team used FDM 3D printing in the prototype stages for a while. But heading into mass production—especially for injection molding—would risk added cost and time if they worked with different suppliers for 3D printing and injection molding processes. Although the team is highly experienced in electrical and electronics, they needed guidance on mechanical and aesthetic aspects for plastic parts, including mold manufacturing, mold design, insert placement and assembly, and color selection.

- Lightweight, Durable Plastic Housings: Selecting materials that withstand external factors and vibration while keeping the bike ergonomic.

- Rapid Iteration: Continuous design updates based on customer feedback; tight delivery schedules often demand new molds and production runs quickly.

- Cost-Effective, Single Supplier: They sought an all-in-one platform offering budget-friendly solutions instead of juggling multiple workshops.

- Storage & Logistics: Managing mold preservation and re-produce parts whenever stock is needed.

A Single Platform from 3D Printing to Injection Molding

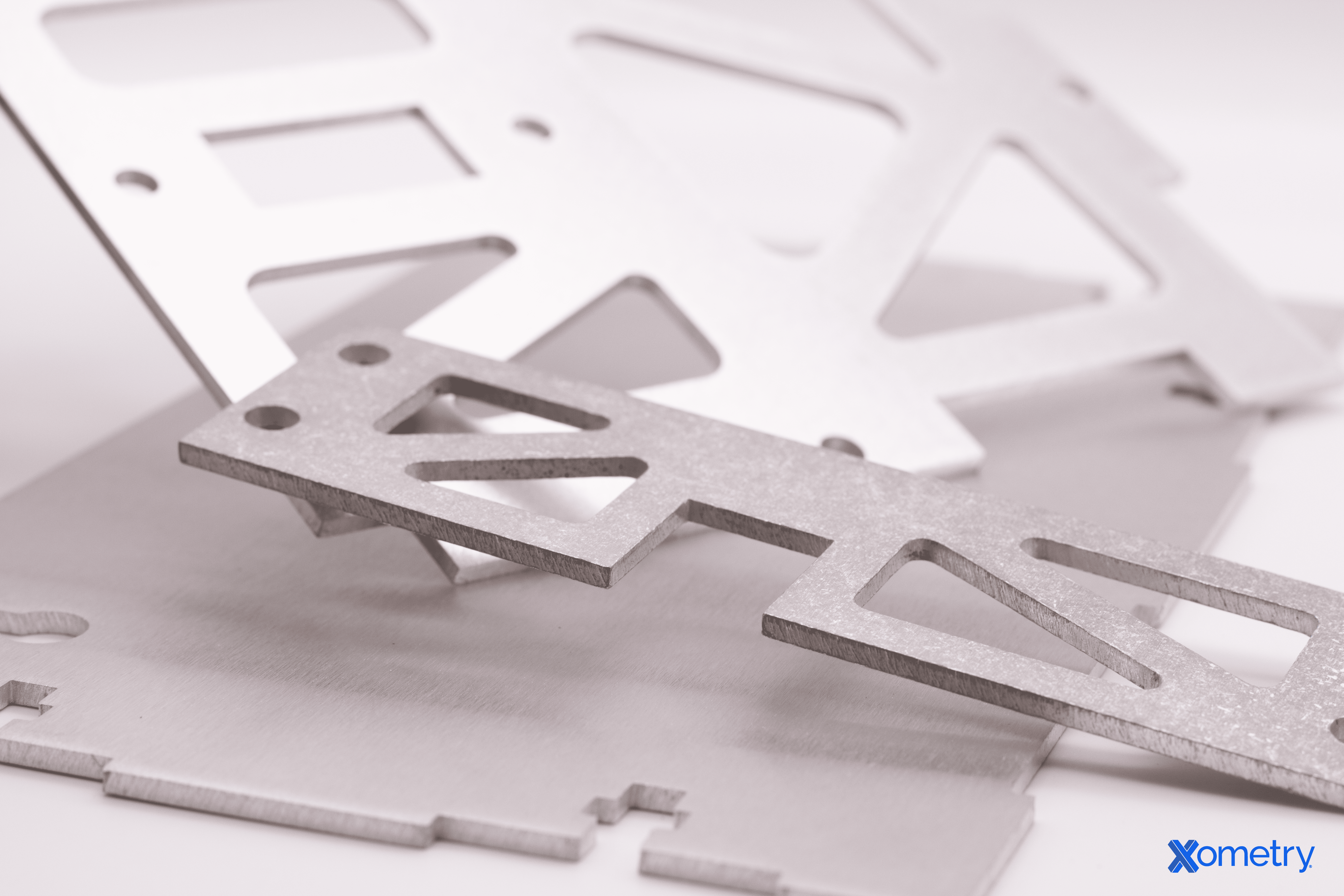

The partnership between Byqee and Xometry Türkiye began in 2021 with FDM 3D printing for prototype projects. Later, when injection molding became necessary, the team used MJF 3D printing to finalize mold testing and analysis, seamlessly transitioning to the injection molding phase.

Byqee’s team occasionally utilized the Target Price Order quoting option to communicate its budget, while Xometry sought the most suitable offers from both Turkish and international producers. After that:

- Early Design Validation: Prototyping stage completed with dimension and ergonomic checks.

- Design Updates: Following prototype feedback, the design was revised. Frequent meetings with Xometry engineers sped up decisions on everything from design, color options, mold types and more aided by DfM (Design for Manufacturability) analysis.

- Final Approval: Once the design was finalized, they proceeded with injection molding.

Material Selection: PA12 and PA6-GF2

For the 3D printing stage, PA12 was used to produce lightweight parts with sufficient durability for prototyping. For mass production via injection molding, PA6-GF2 (glass fiber–reinforced) was chosen to ensure the necessary balance between rigidity and lightness in mechanical assemblies. By recommending the most suitable material to meet Byqee’s “light but robust” requirement, Xometry enabled the battery and bracket housings to become more resistant to shocks and vibrations.

Quality Control, Sustainability, and Beyond

Byqee’s product development process follows a cyclical path of “R&D → revision → market feedback → re-production.” While the team focuses on eco-friendly solutions such as “battery renewal” and “electric conversion kits” with ongoing R&D, Xometry supports the production process sustainably through quality control and supply assistance:

- Global Supply Network: Byqee leverages Xometry’s global network to scale up its sustainable mobility products effortlessly.

- Quality Control: Ensuring parts meet correct tolerances, inserts fit smoothly, and surface quality is consistent, along with other checks.

- Logistics & Speed: Parts arrive fully ready for final assembly, allowing Byqee to reduce delivery times significantly.

- Mold Storage: Injection molds are stored on Byqee’s behalf; periodic injection runs are performed as needed.

Conclusion: A Long-Term, Rapid Solution Partner

Through Xometry Türkiye, Byqee sped up operations, cut costs, and maintained quality standards by using multiple manufacturing technologies under a single supplier. In particular, DfM analyses, color selection, insert installation, and quality checks—guided by Xometry—kept Byqee on schedule.

Looking ahead, Byqee aims to expand into other e-mobility vehicle solutions, battery renewal technologies, and deeper access into European markets. With the flexibility and diverse manufacturing capabilities offered by Xometry, they seem poised to explore new product segments.

Discover more about Byqee: https://byqee.tech/tr/

Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)