This radius is influenced by several factors including the type of material, its thickness, and the bend angle. Using a reference table and interactive calculator can help product designers and engineers determine the optimal bend radius for their projects.

Determining the Right Bend Radius for Sheet Metal

Rule of Thumb for Bend Radius

A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. Below is a table summarizing the recommended minimum bend radii for different materials, including aluminium, steel and stainless steel.

| Material | T: 1-6 mm | T: 6-12 mm | T: 12-25 mm |

| Aluminium | 1 x T | 1.5 x T | 2-3 x T |

| Steel | 0.8 x T | 1.2 x T | 1.5-2.5 x T |

| Stainless Steel | 2 x T | 2.5 x T | 3-4 x T |

Interactive Air Bend Force Chart

| V, mm i | 6 | 8 | 10 | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 200 | 250 | 320 | 400 | 500 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| b, mm i | 4 | 5.5 | 7 | 8.5 | 11 | 14 | 17.5 | 22 | 28 | 35 | 45 | 55 | 71 | 89 | 113 | 140 | 175 | 226 | 280 | 350 | ||

| ir, mm i | 1 | 1.3 | 1.6 | 2 | 2.6 | 3.3 | 4 | 5 | 6.5 | 8 | 10 | 13 | 16 | 20 | 26 | 33 | 41 | 53 | 65 | 83 | ||

| t, mm i | 0.5 | 4 | 4.4 | F, t/m i | ||||||||||||||||||

| 0.8 | 4 | 5.5 | 7 | |||||||||||||||||||

| 1 | 11 | 8 | 7 | 6 | ||||||||||||||||||

| 1.2 | 16 | 12 | 10 | 8 | 6 | |||||||||||||||||

| 1.5 | 17 | 15 | 13 | 9 | 8 | |||||||||||||||||

| 2 | 27 | 22 | 17 | 13 | 11 | |||||||||||||||||

| 2.5 | 35 | 26 | 21 | 17 | 13 | |||||||||||||||||

| 3 | 38 | 30 | 24 | 19 | 15 | |||||||||||||||||

| 4 | 54 | 42 | 34 | 27 | 21 | |||||||||||||||||

| 5 | 67 | 52 | 42 | 33 | 26 | |||||||||||||||||

| 6 | 75 | 60 | 48 | 38 | 30 | |||||||||||||||||

| 8 | 107 | 85 | 68 | 53 | 43 | |||||||||||||||||

| 10 | 134 | 105 | 85 | 67 | 53 | |||||||||||||||||

| 12 | 153 | 120 | 95 | 78 | 60 | |||||||||||||||||

| 15 | 188 | 150 | 120 | 95 | 75 | |||||||||||||||||

| 20 | 215 | 170 | 135 | 108 | 85 | |||||||||||||||||

| 25 | 265 | 210 | 170 | 130 | 105 | |||||||||||||||||

| 30 | 300 | 240 | 190 | 150 | 120 |

Sheet Metal Bending Radius Calculator

| 4 | 17.5 | 25 | 67 |

| 5 | 22 | 32 | 52 |

| 6.5 | 28 | 40 | 42 |

| 8 | 35 | 50 | 33 |

| 10 | 45 | 63 | 26 |

| ir, mm | b, mm | V, mm | F, t/m |

- 0.5

- 0.8

- 1

- 1.2

- 1.5

- 2

- 2.5

- 3

- 4

- 5

- 6

- 8

- 10

- 12

- 15

- 20

- 25

- 30

Determining Right Bend Radius with the Air Bend Force Chart

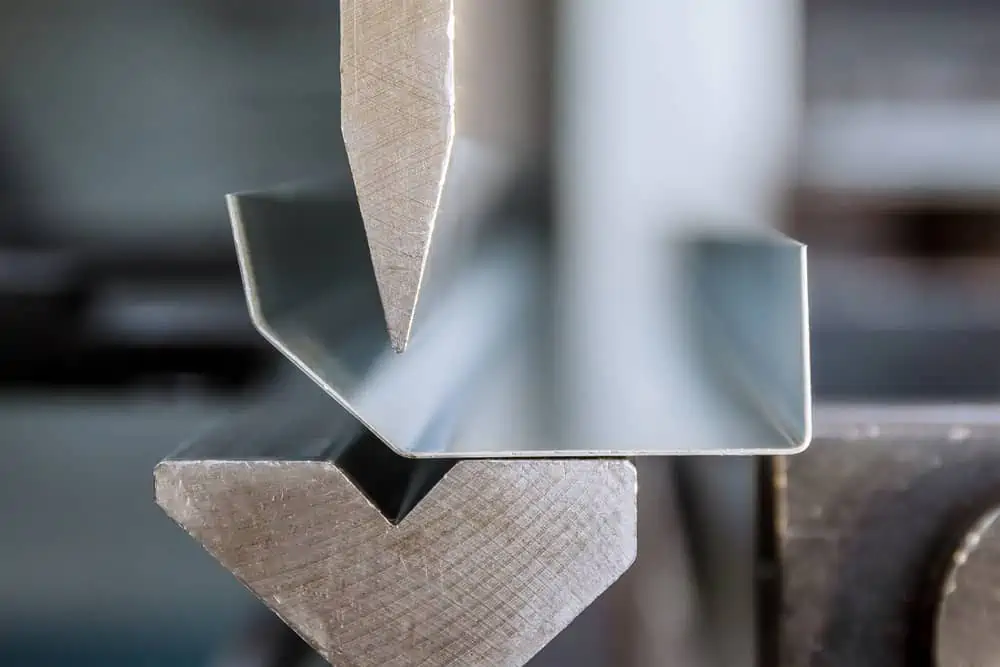

V-Bending and Air Bending

Manufacturers commonly use V-bending and air bending techniques to achieve precise bends in sheet metal. V-bending involves placing the sheet metal over a V-shaped die and pressing it with a punch to create the bend. Air bending uses a similar method but allows for more flexibility by not forcing the material to conform entirely to the die shape, which helps achieve different bend angles.

Impact of Sheet Thickness on Bend Radius and Other Parameters

The thickness of the sheet metal directly impacts the bend radius and other critical bending parameters, such as V-opening, bending force, and flange length. Understanding this relationship is crucial for ensuring the quality and durability of the bend, as well as optimizing the manufacturing process.

Bend Radius

Thicker sheets require larger bend radii to avoid cracking or damaging the material. This is because bending induces tensile and compressive stresses on the sheet. Thicker sheets are less flexible and more prone to cracking if the bend radius is too small. Ensuring an appropriate bend radius helps maintain the integrity of the material and prevents defects.

V-Opening

The V-opening of the die, which is the gap into which the sheet metal is pressed to form the bend, must be adjusted according to the thickness of the sheet. Thicker sheets require a larger V-opening for the following reasons:

- Accommodation of material: A larger V-opening provides sufficient space for the thicker material to bend without excessive force.

- Reduction of force concentration: A wider opening helps distribute the bending force more evenly across the material, reducing the risk of cracking or deformation.

Bending Force

The bending force required to achieve a desired bend increases with the thickness of the sheet metal. This is due to the greater resistance of thicker materials to deformation. The relationship can be summarized as follows:

- Increased resistance: Thicker sheets have more material to deform, which requires more force.

- Tooling requirements: The tools and machinery used must be capable of exerting the higher force needed for thicker sheets.

Flange Length

Flange length, which is the length of the sheet metal extending from the bend, is also affected by sheet thickness:

- Minimum flange length: Thicker sheets generally require a longer minimum flange length to prevent the material from buckling or deforming during bending.

- Tooling and setup: Adequate flange length ensures that the sheet is properly supported during the bending process, contributing to a more accurate and consistent bend.

How Manufacturers Use the Air Bend Force Chart for Sheet Metal Bending

Manufacturers use air bend force charts to determine the appropriate die V-opening, minimum flange length, and bending force required for specific sheet thicknesses and bend radii. Here’s how the process works:

- Find the needed sheet thickness: Start by locating the required sheet thickness in the first column.

- Identify the required die V-opening: This is the primary factor manufacturers consider. It helps them choose the right tools for bending a sheet.

- Determine the required bending force: Look at the central part of the table to find the bending force in tons per meter (t/m).

- Identify minimum flange length and achievable internal radius: Find the minimum flange length suitable for the selected V-opening, as well as the achievable internal radius for this sheet thickness.

Practical Example: 90-Degree Bend of a 4mm Steel Sheet

Using the chart above, you can follow these steps:

- Suitable V-Opening: For a 4mm steel sheet, the suitable V-opening is 20-50 mm.

- Minimum Flange Length: Each flange should be at least 14-35 mm.

- Achievable Bend Radius: The achievable bend radius is 3.3-8 mm.

- Optimal Values: The blue values in this chart are optimal.

For your convenience, the calculator below the table organizes these values in a more compact and user-friendly way:

| Note: This chart is relevant for sheets bent into a 90° angle. The default chart (when Metric and Steel are selected) applies to structural steels with an approximate yield strength of 400 MPa. For aluminum, multiply the force values by 0.5; for stainless steel, multiply by 1.5 (in our chart you can just switch between the needed materials) This chart is for reference only. |

Conclusion

This article, along with the interactive chart and calculator, illustrates how sheet thickness affects various bending parameters, including the bend radius. However, bending parameters also depend on the specific material of your sheet. The same material sourced from different suppliers can have varying properties, so it’s crucial to consult with your material supplier when making design decisions.

Additionally, you can rely on your part manufacturer. Their experience and expertise can guide you in making the right decisions, and they can determine the optimal bending parameters through testing.

In most cases, when designing parts, you can follow the rule of thumb for minimum bend radius and then seek feedback from your parts manufacturer. Xometry’s engineers and manufacturing partner network always conduct a manufacturability audit and provide feedback before proceeding with sheet metal fabrication, ensuring that your parts are designed and manufactured to meet your specifications.

At Xometry Europe, we offer highly accurate sheet metal services as well as design consultancy services (DFM).

Through our Instant Quoting Engine and our network of over 2,000 manufacturers, we ensure that you experience a seamless part production process, from quoting to doorstep delivery.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  1

1

Comment(1)