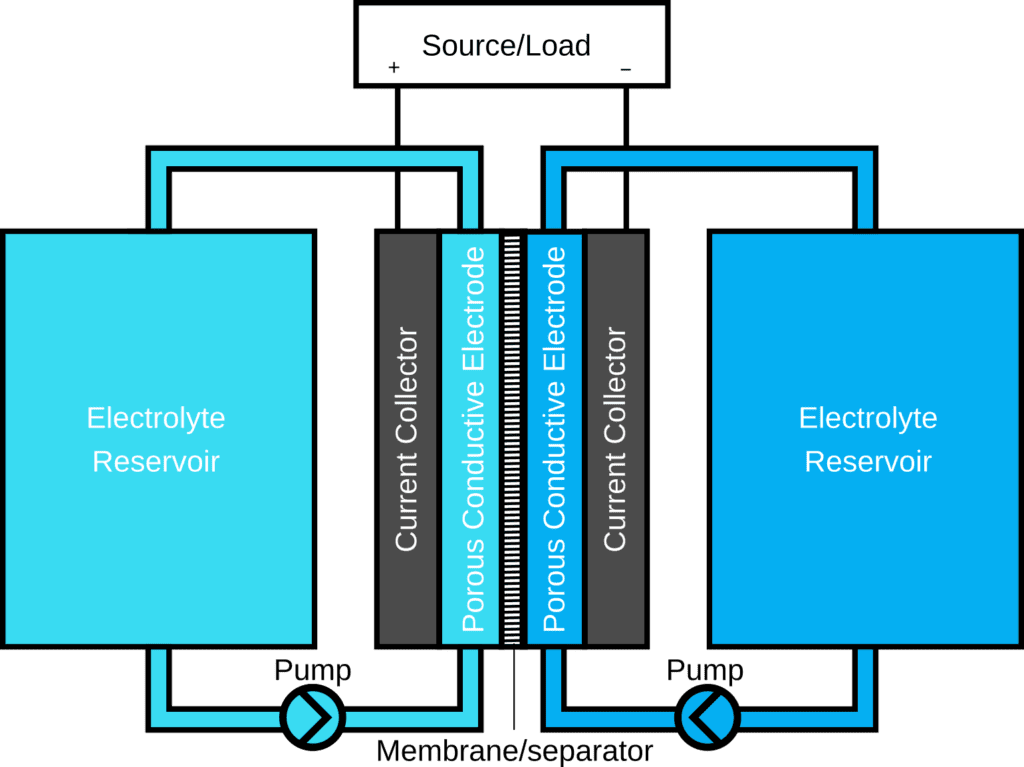

At FBRC, we are interested in flow batteries because of their potential to be low-cost, safe, and sustainable ways to store renewable energy. We have proven it is possible to develop them with minimal resources in amateur laboratory settings, like home laboratories and hackerspaces. This low-overhead R&D is possible because of their relatively simple construction and water-based electrolytes—compared to lithium-ion batteries, for example, which demand much more costly facilities for both development and production.

By helping make this technology accessible and taking an open-source development approach, we hope that innovation in flow batteries can accelerate. Ultimately, we expect to produce the designs and initial prototypes for a working flow battery, released under an open-source license that allows for commercial use.

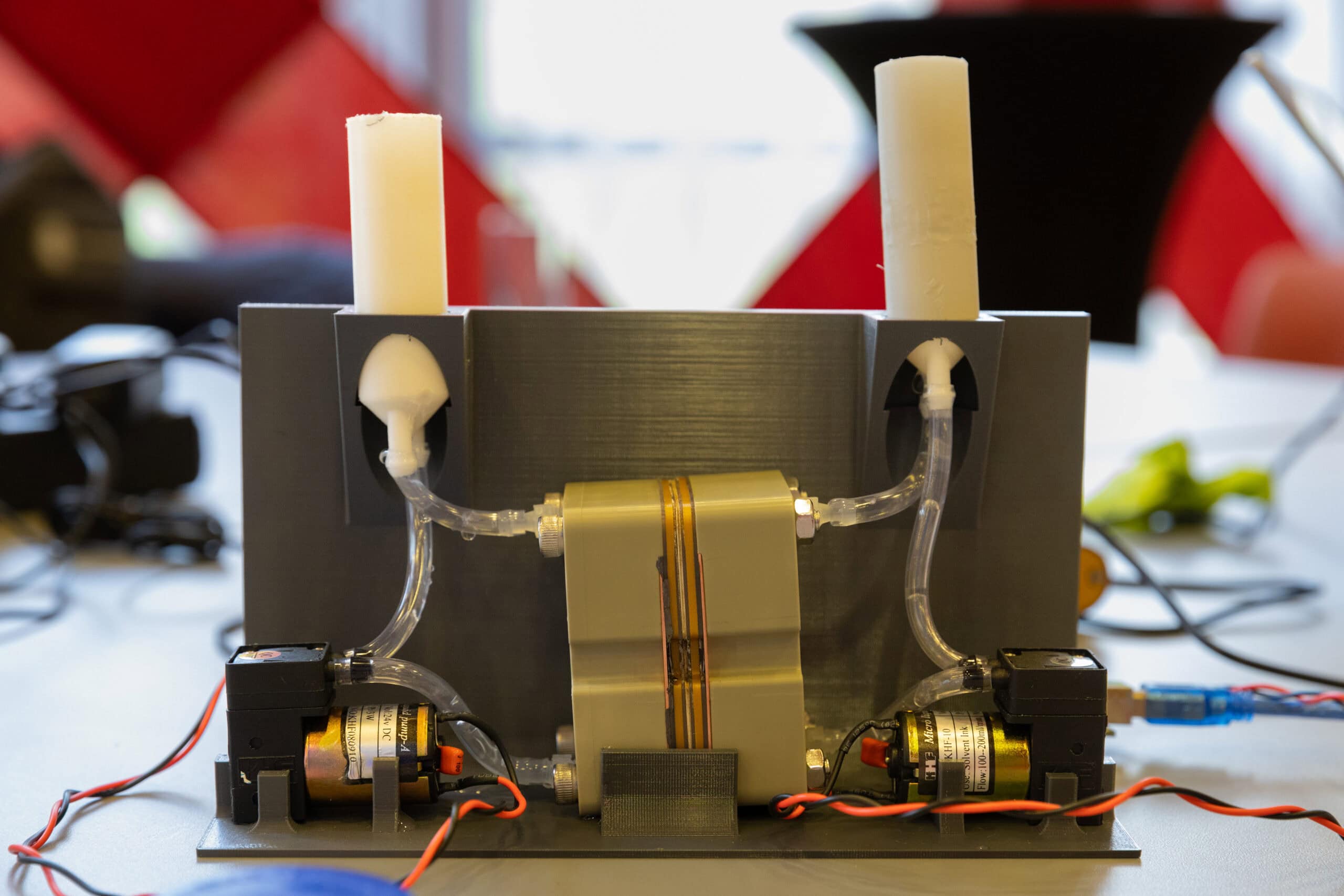

To get there, however, we need to be able to precisely test intrinsic properties of these batteries at small scales. This is why we set out creating a development kit, to allow for reproducible research testing and instructional teaching use.

From Hackerspaces to High-Precision Parts: Engineering an Open-Source Flow Battery

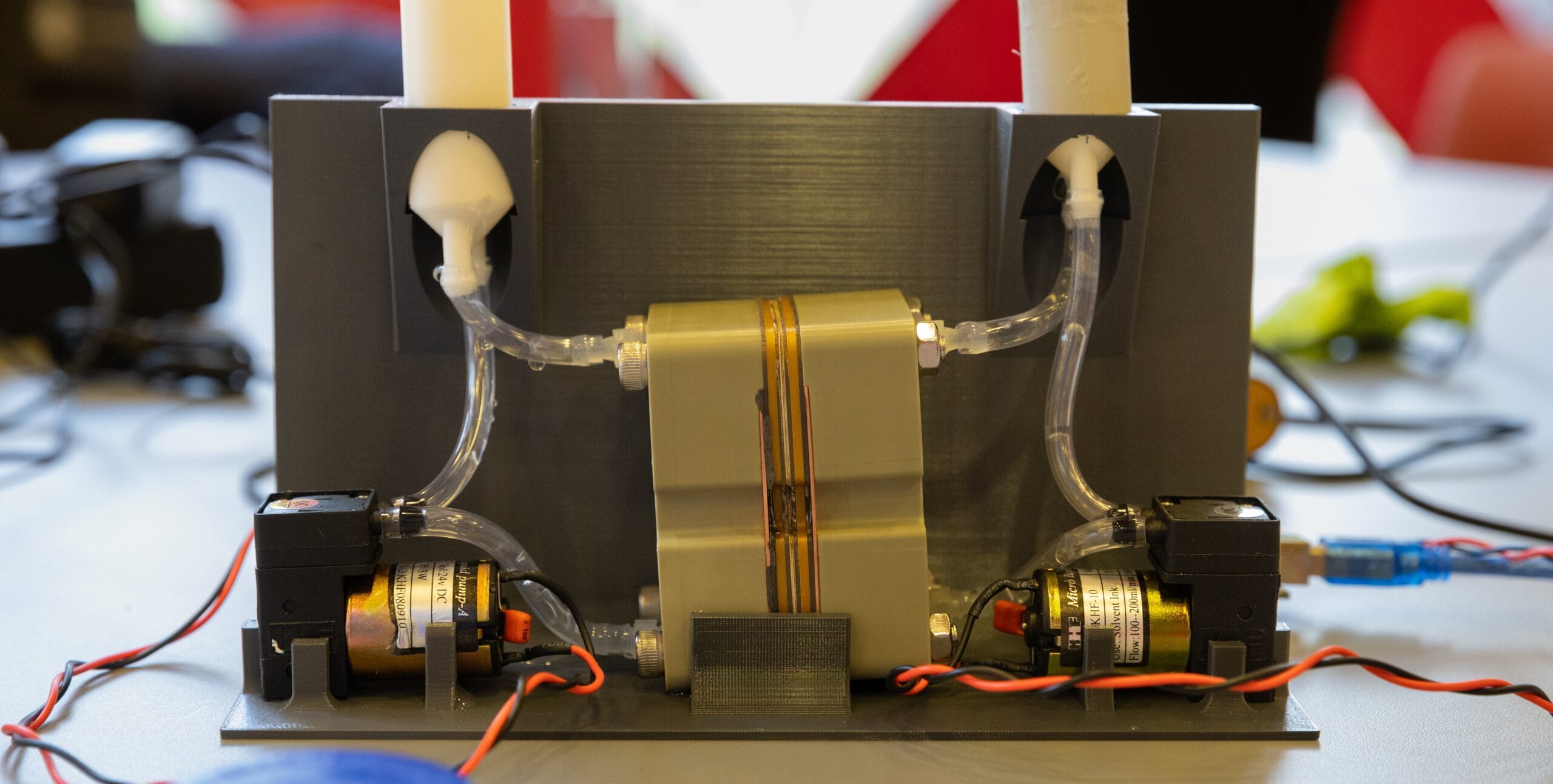

Our team initially met through the internet—by stumbling upon each others’ blogs—and we happened to all live in different countries in the EU. Our development process has been geographically distributed—I would design parts in France, Josh would fabricate them at Lili’s Proto Lab in the Netherlands, and then send them to Daniel in Spain for experimental testing. This worked well enough for initial prototyping with FDM printing.

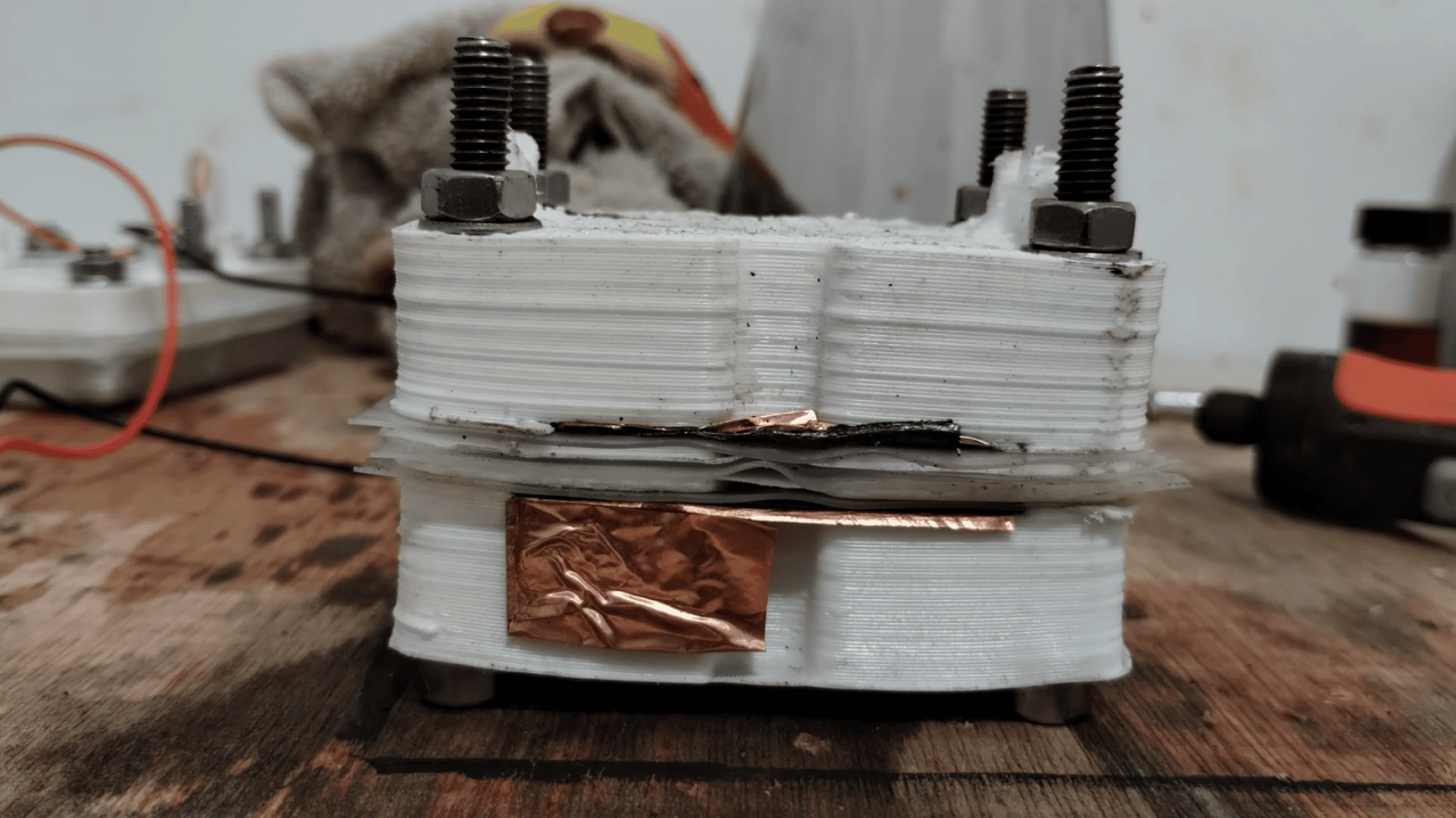

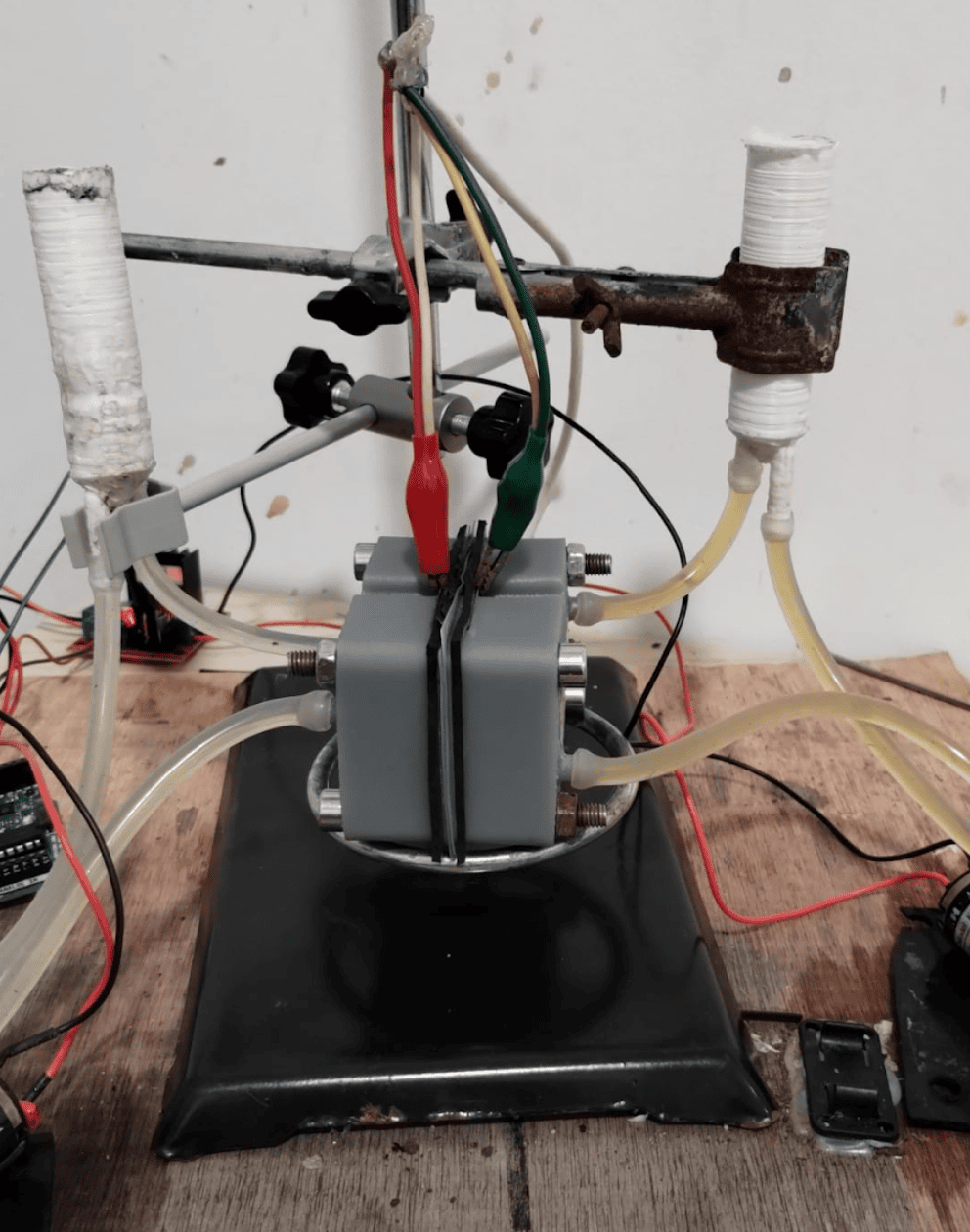

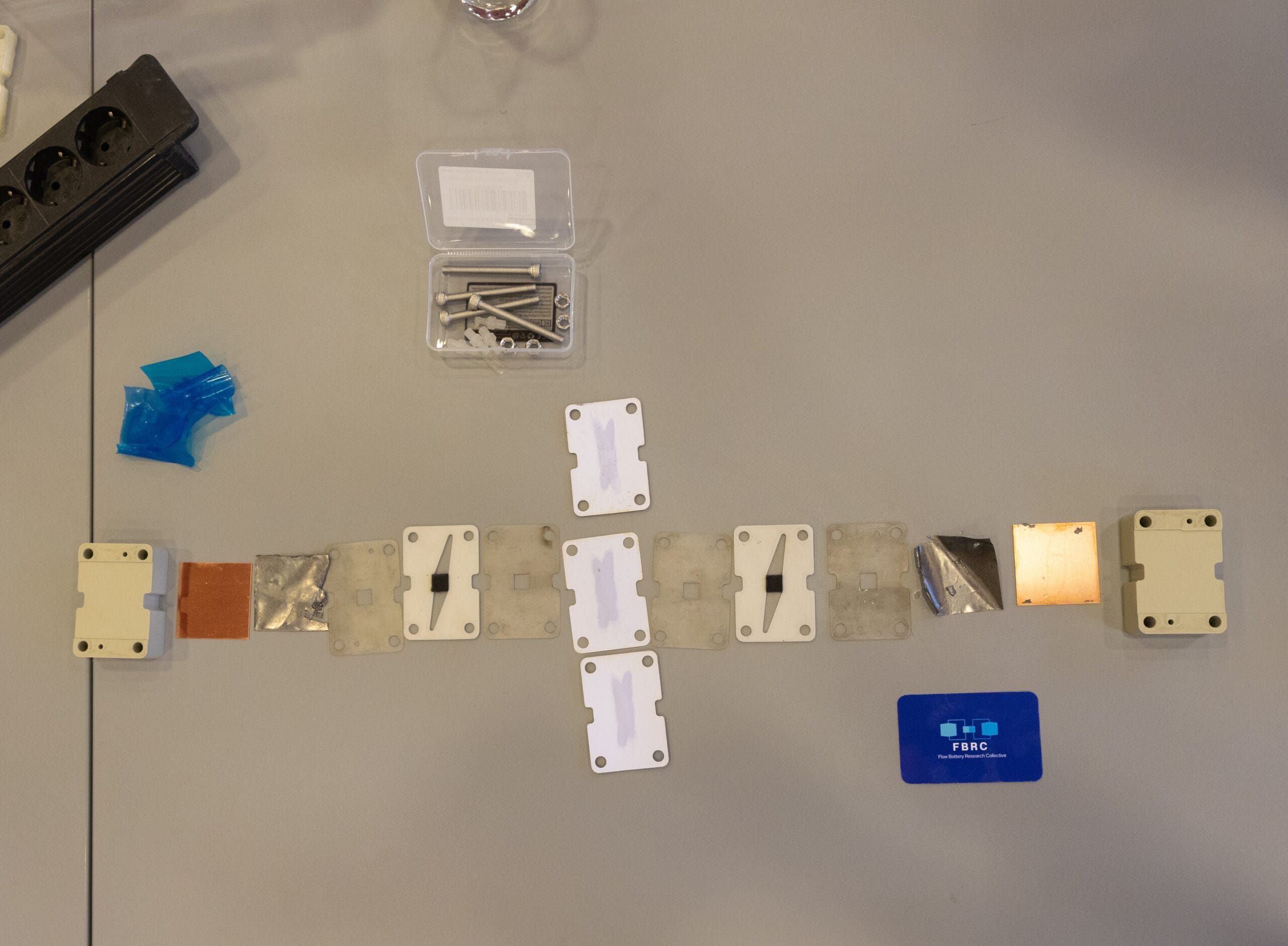

We wanted to develop an affordable flow battery development kit that was easy to manufacture and source components for. One key innovation was developing a cell that could use cheap and available graphite foil gasket material as a current collector, instead of more expensive and hard-to-get bipolar plate material. In addition, beyond just the flow cell and electrolyte, we wanted to develop and open-source the entire system: pumps, tubing, reservoirs, jigs, power electronics, etc. The devil is in the details, and we wanted to have a complete system to lower the barrier to entry as much as we could.

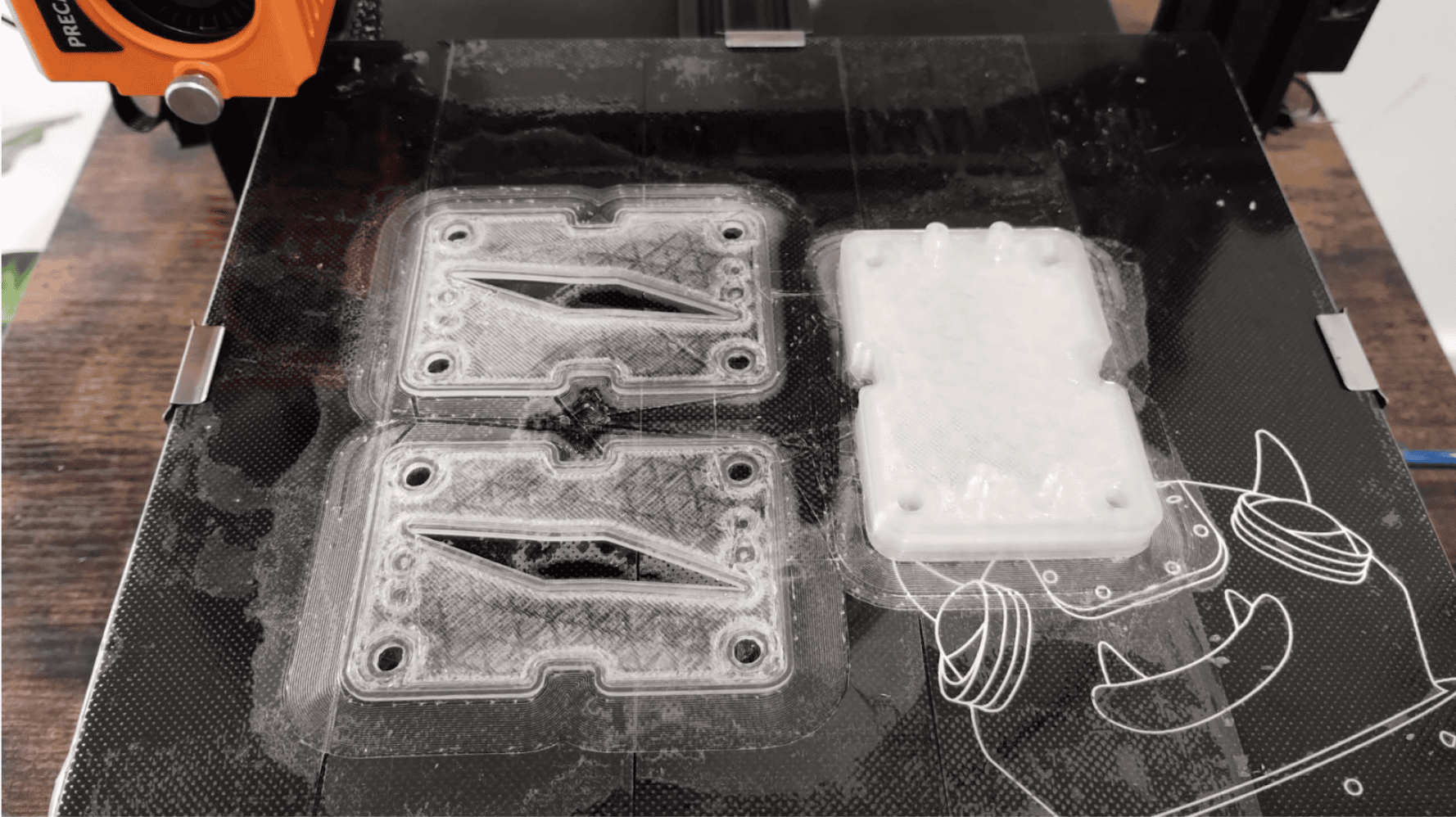

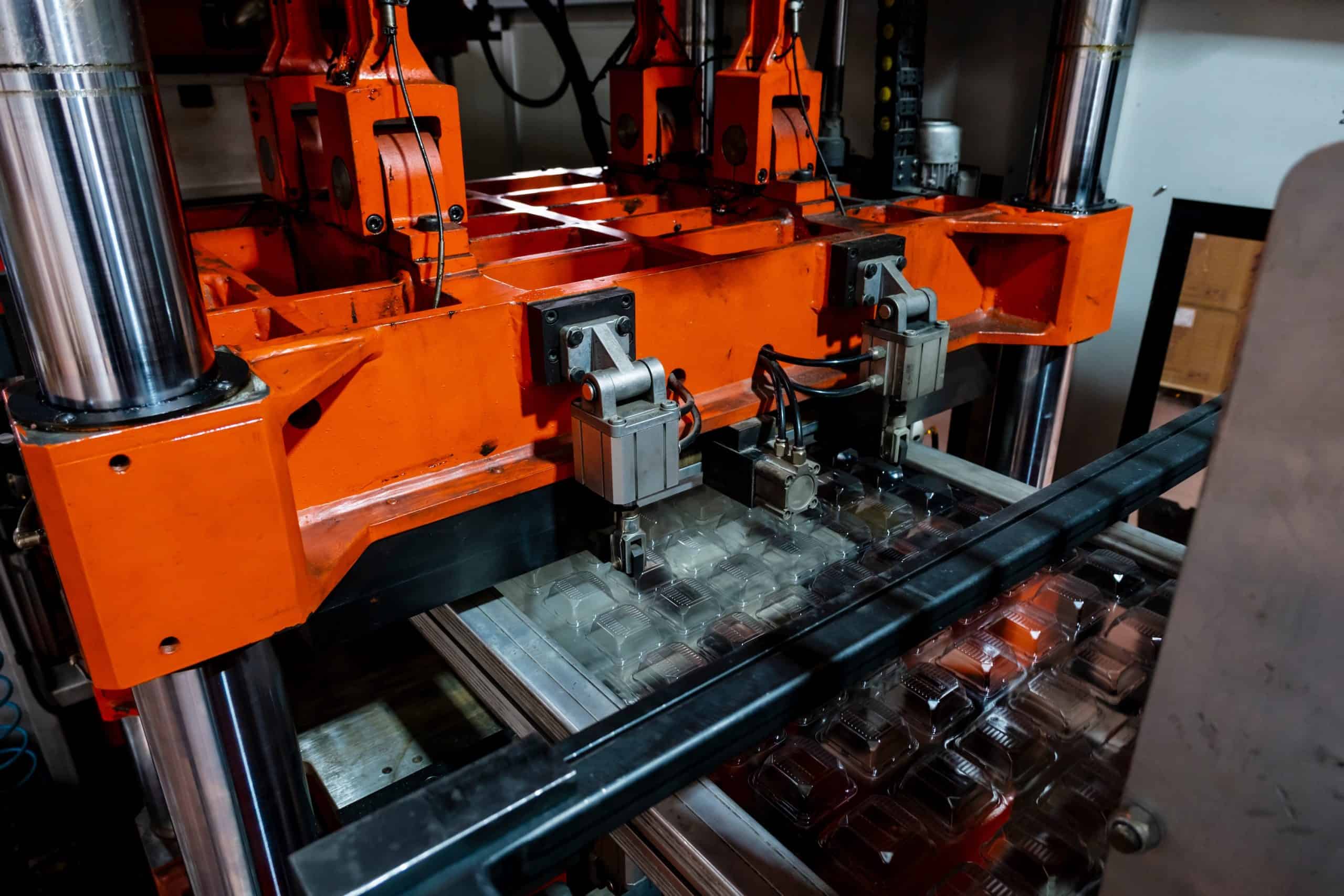

The initial version of our cell required machined polypropylene parts. We tried FDM printing, but the parts were not dimensionally accurate or rigid enough, and resin prints were not chemically compatible with our electrolytes.

Scaling Innovation: How Digital Manufacturing Enables Open-Source Energy Storage

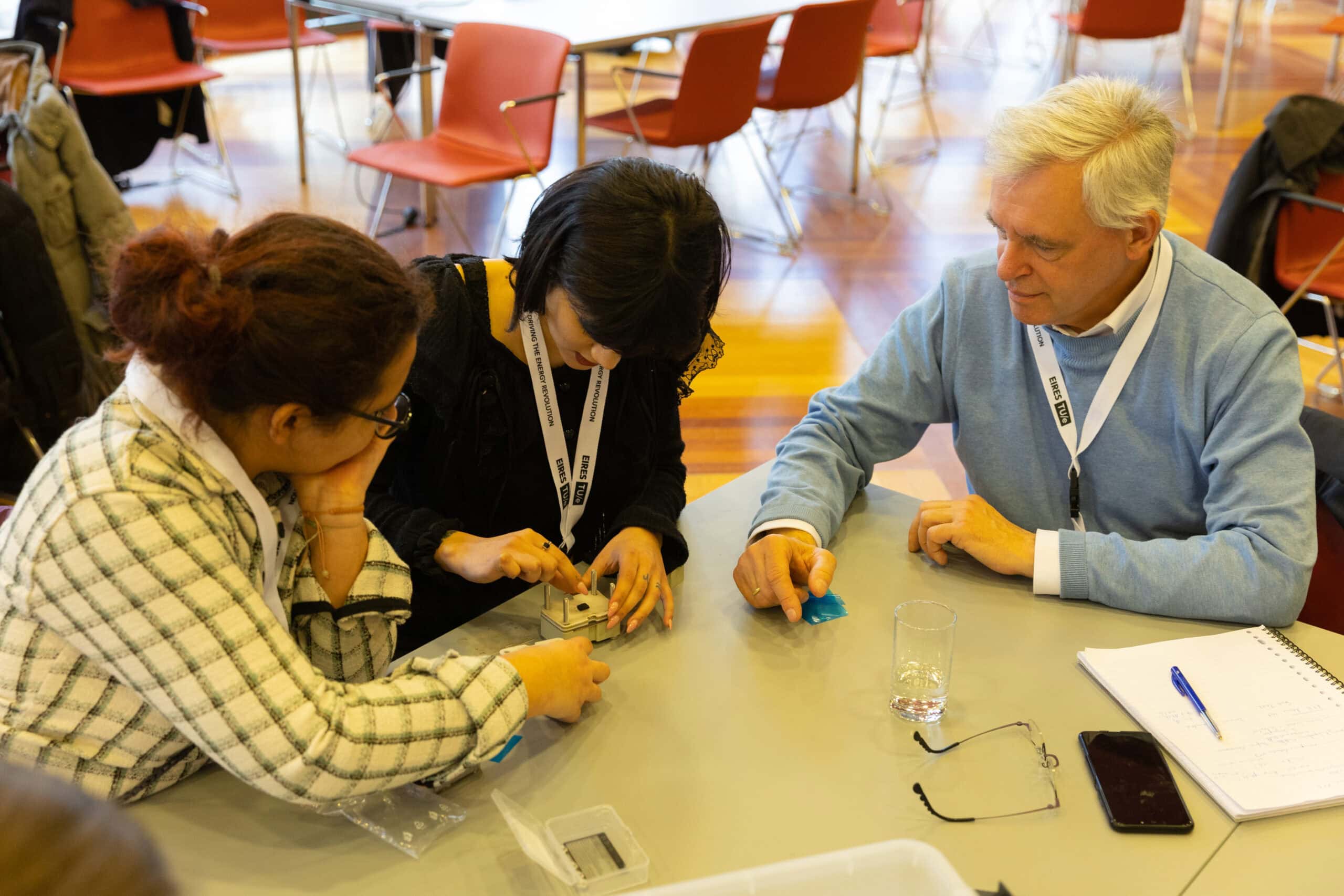

Prof Sanli Faez offered to host us for a workshop in the Netherlands through his FAIR Battery project, in which we would introduce the project and assemble cells (with water) with workshop participants. We wanted to aim for 10 complete kits, which meant we needed 20 machined cell bodies in a short amount of time.

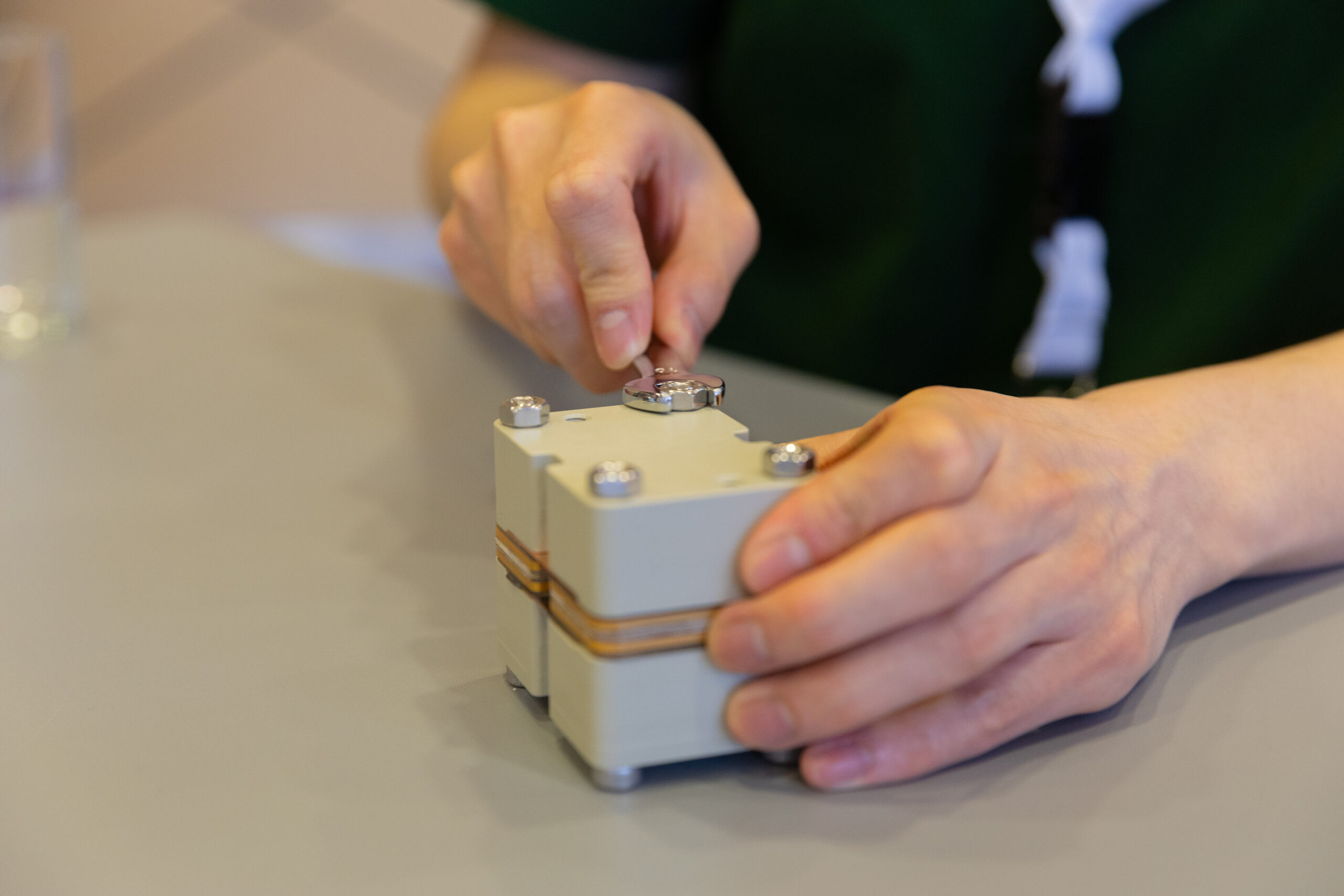

This is where Xometry came in. We are researchers, and that is what we are best at—not fabrication! For certain applications, there is no substitute for milled parts, and we turned to Xometry to produce these components for our workshop. This is because we were unable to produce sufficiently rigid and fluid-tight parts in polypropylene with FDM printing, and SLA resin printing also could not give us the results we needed. The charged electrolytes we used for testing, which include triiodide species, are reactive with other FDM materials like ABS that might be otherwise stable in acid electrolytes. As a result, once we knew the geometry and approach of our cell was functional, we decided to mill these from solid polypropylene. The only change needed was to add tapped holes to place commercially available barbed fittings into, since that geometry was not suitable for milling.

We received the parts in time for the workshop and had no issues with their assembly on-site. The workshop was successful and went off without a hitch.

Since the workshop, we have made progress towards an improved version of the kit, which simplifies the manufacturing process somewhat. We no longer need machined plastic parts, but there are some metal components that are still best fabricated using subtractive machining.

As open-source hardware developers, we have been jealous of the ease with which software developers can clone a repository and make contributions. Engineers that develop printed circuit boards also now have standardised open-source tools like KiCAD and a wide array of manufacturers that offer quick turnaround times, lowering the barrier to development and shortening iteration cycles for PCB-based projects.

With digital fabrication services and open-source mechanical CAD tools like FreeCAD, it will be easier than ever for custom parts to be developed and tested by a global community. When 3D printing simply won’t do, projects like ours can slow down or stop because of the bottleneck of physical access to a machine shop with conventional tools and knowledgeable machinists. Without this limitation, projects like ours can innovate, iterate, and allow others to reproduce and contribute to our work much more easily than before.

You can follow along as our project progresses here, and hop in our forum if you have any questions or would like to get involved!

How have digital manufacturing tools helped accelerate your development? What lessons have you learned from open-source hardware projects? We’d love to hear about your experiences.

**@****al.coop“>Share Your Engineering or Product Design Story

Share Your Story!

Share your engineering and product design journey and get a €300 reward! Showcase your innovative solutions and best practices with our community.

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account  0

0

Comment(0)